-

About Us

-

Products Center

-

Human Resources

-

Investor Relations

-

Carbon/Carbon ComPositefurnace Board

Product description:

Carbon/carbon furnace board are specially designed for high-temperature graphite furnace, made of carbon/carbon composite materials. It has a series of excellent properties, including stable electrical resistance, high wear resistance, good thermal shock resistance, larger volume, etc. It is an excellent high-temperature thermal field material and an upgraded material of traditional graphite furnace board.

Application area:

Graphitization of negative electrode materials for lithium batteries.

keyword:

Category:

Detailed Introduction

Features:

► Big volume

► Stable resistance

► High purity

► Good thermal shock resistance

Product performance:

| Technical specifications | Parameters |

| Thickness(mm) | ≤30 |

| Tensity(g/cm3) | 1.4-1.5 |

| Bending strength(MPa) | ≥30 |

| Compressive strength(MPa) | ≥60 |

| Resistivity(μQ•m) | 15-25 |

| Ash content(ppm) | ≤800 |

The model specifications can be designed and produced according to customer requirements

Related Products

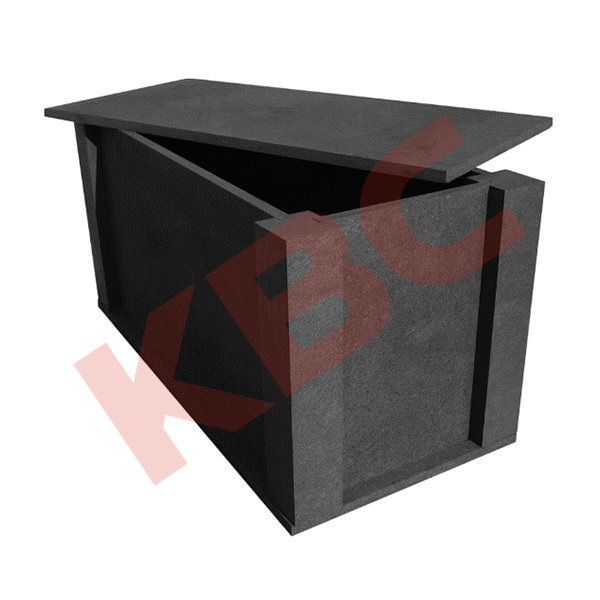

Carbon/Carbon Composite Sagger

Product Description:

A carbon/carbon composite sagger is a high-temperature container made of carbon/carbon composite material. It has a series of excellent properties such as light weight, high strength, good thermal shock resistance, high purity, and strong wear resistance, making it an excellent high-temperature thermal field material and an upgraded material for traditional graphite saggers.

Application field:

Containers for sintering of negative electrode materials for lithium-ion batteries, positive electrode materials for lithium iron phosphate, and high-temperature powder metallurgy sintering boats.

Application areas: high-temperature treatment of lithium-ion battery negative electrode materials, photovoltaic, powder metallurgy, industrial high-temperature furnaces, and other related fields.

Carbon/Carbon Composite Crucible

Application fields: High-temperature heat treatment industry, including lithium-ion battery negative electrode materials, purification of diamond carbon source materials, rare earth smelting, precious metal smelting, etc.

Get Product Quotes For Free

+86-0737-6202107 (Securities Department)

WeChat official account